WALNUT BLASTING - Inlet path blasting

Also for Walnut blasting you are at Chip Performance at the right place.

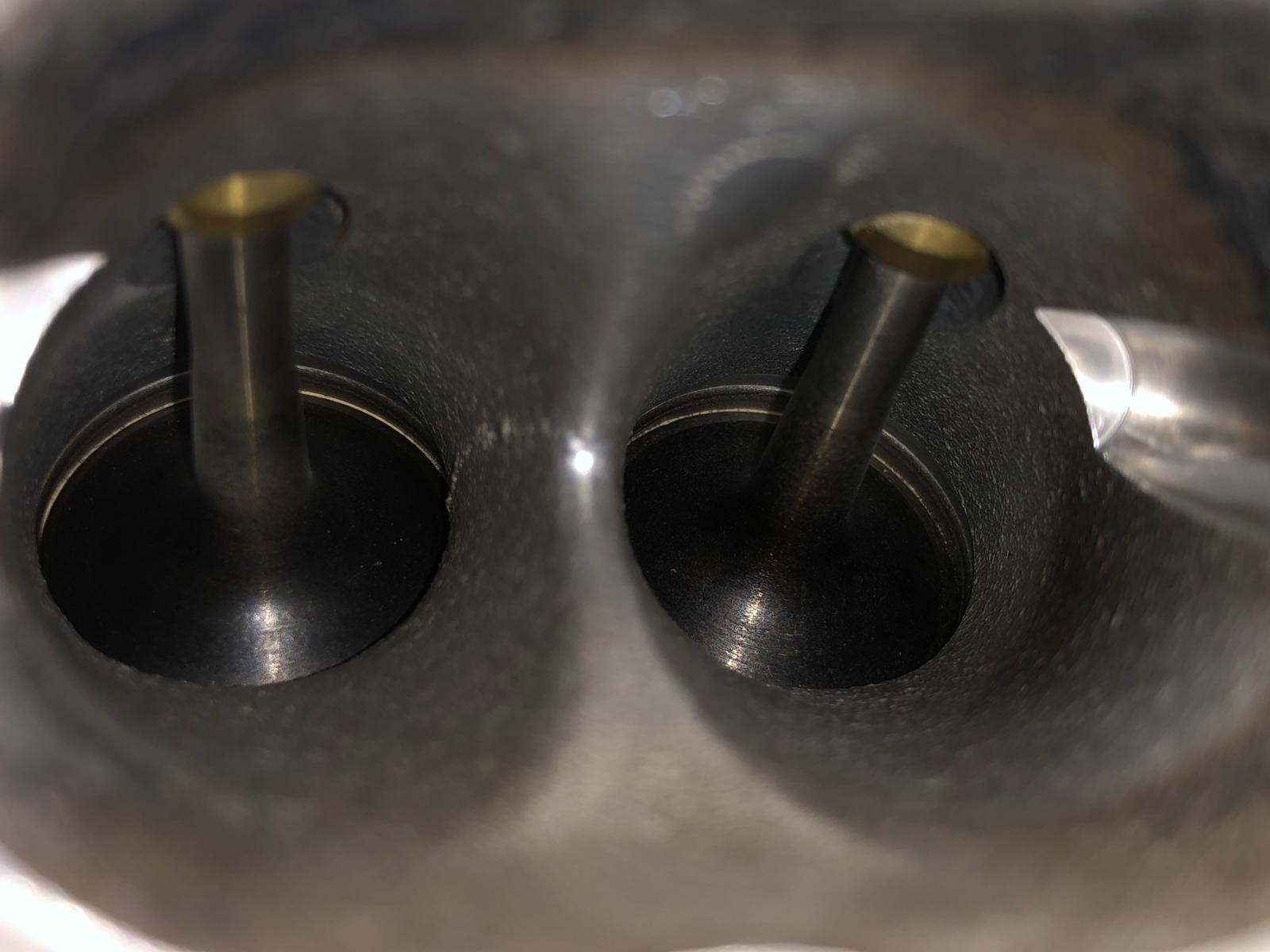

Direct injected gasoline and diesel engines suffer from carbon / carbon deposits in the intake ducts and on the valves.

The injectors do not inject before the valves, like indirectly injected engines, but directly into the cylinder. The oil vapors carried by the crankcase ventilation settle against the walls of the inlet section. This (oil) deposit results in carbon / carbon deposition and this creates a narrowing. This can result in:

- Reduced engine power

- Irregular running of the motor with a light motor load

- Various engine / lambda failures

- Bad / irregular idling

- Black smoke from the exhaust

- Increased fuel consumption

Car brands where carbon / carbon deposition is a common problem are Volkswagen, Audi and Seat (T) FSI / TSI engines, THP engines (Peugeot, Citroën, MINI) and BMW N engines after 2008 (including N43, N54, N55). Chip Performance offers the right solution for this.

Solution: Walnutblasting!

The only correct solution to remove the carbon / carbon deposit is to blast the inlet section with walnut granulate, aka Walnut Blasting.

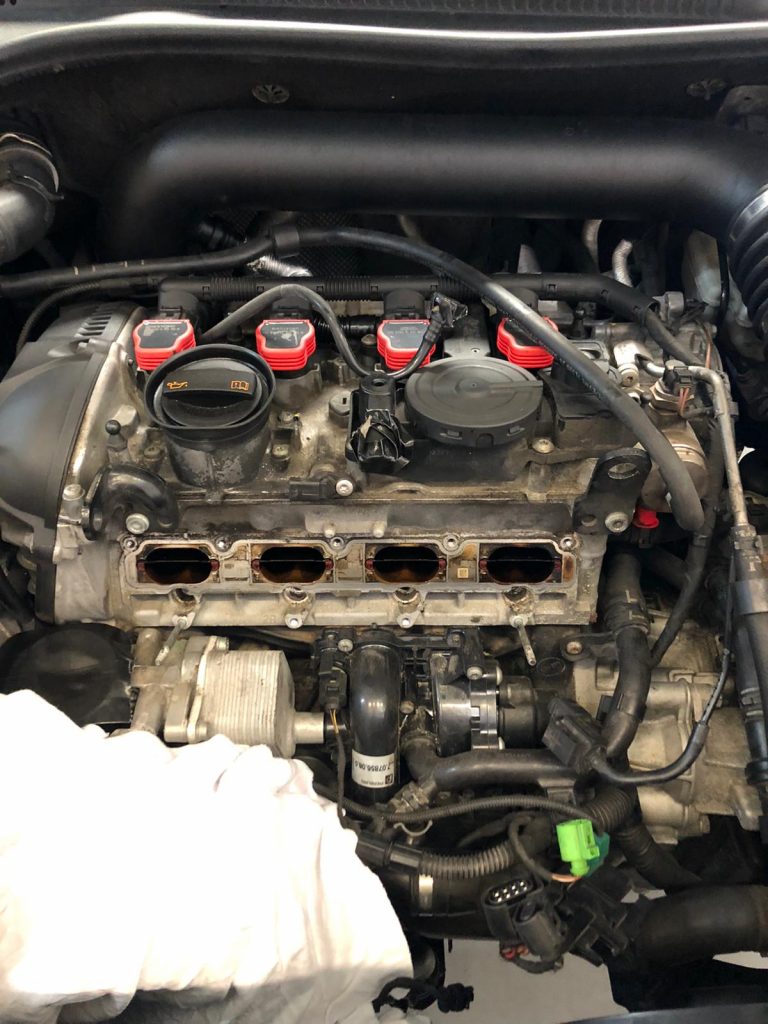

Chip Performance has special equipment (Walnut Blaster) through which the inlet channels are completely blasted and cleaned. During the cleaning process, the intake manifold is always removed, as are the crankcase ventilation * and the injectors *.

To prevent granulate particles in the cylinder during the blasting of the inlet, we ensure that the inlet valves per cylinder are always completely closed. The other inlets are covered so that no dirt, granulate or dust can fall into the cylinder.

We install new gaskets, seals and oil rings at all times. We also check the crankcase ventilation * for correct operation, the camshaft successor * is checked and we recommend mounting a Forge PCV delete kit for TFSI engines. As a result, less pollution occurs.

Because there is often also a lot of carbon deposits on the injectors, we recommend that the injectors be cleaned ultrasonically and replaced if necessary. We also do this ourselves.

In addition, we are seeing more and more direct-injection diesels with densely charred intake routes, so that the so-called swirl flaps no longer work. These swirl flaps, butterfly valves in the intake section, then get stuck, causing engine problems such as content, smoking and higher fuel consumption.

With VAG & BMW motorcycles you can choose to have the Swirl flaps removed *. This results in a better air flow, smoother ride and more power. More information about this is on request.

* Not in all cases. This differs per type.

We take photos of all work so that you can always see what the result is.

Prices for a complete cleaning of your intake from €399,- incl. VAT