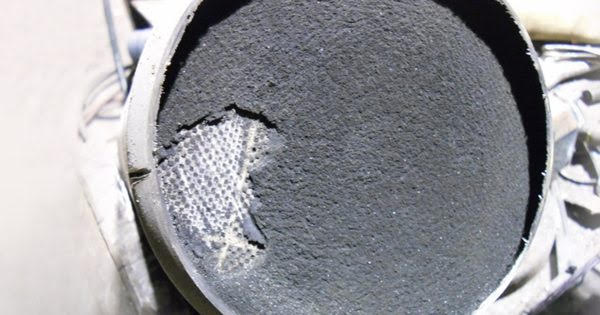

The soot filter / DPF

A number of agricultural machines are now equipped with a particulate filter (DPF). The purpose of this is to allow the exhaust gases to pass through and to collect the soot particles. This is of course good for the environment, but also certainly has disadvantages for the engine.

The soot particles are temporarily stored in the soot filter (DPF). A regeneration process happens every few hours because the filter is saturated. This is measured by the pressure sensor in the diesel particulate filter (DPF). During this process, the soot particles are burned at a high temperature. To achieve this, a considerable amount of diesel must be injected into the diesel particulate filter (DPF). Regeneration is therefore the destruction of stored soot particles at an extremely high temperature. A disadvantage of this is that it has a negative effect on fuel consumption. Generally, regeneration takes place automatically during work.

Problems with soot filters:

-

When the engine is almost not at operating temperature, the combustion is not optimal and the emission of the soot particles increases. As a result, the soot filter will become saturated more quickly and sooner.

-

Because the engine does not reach operating temperature, the soot filter will reach a temperature that is too low to start the regeneration process. The result is that the particulate filter becomes clogged. This will reduce the engine power and the computer will give an error message. The dealer can empty the particulate filter with a forced regeneration. Repetitive or late intervention can lead to damage to the particulate filter. This shortens the life of the particulate filter.

-

Fuel consumption increases drastically, because the regeneration process costs a lot of fuel.

Conclusion:

The maintenance costs increase and the life of the particle filter is seriously shortened. Partly the fuel consumption will be quite hefty.

What can Chip Performance do for you?

In practice, it turns out that quite a few problems arise with the diesel particulate filter. The costs can amount to a few thousand euros for the complete replacement of a particulate filter. We offer the solution to program the particulate filter. You must ensure that the particulate filter is emptied or that a replacement pipe is installed. You can have this done at your garage or dealer. If this is not possible, we can take care of this for you. We program the diesel particulate filter from the software as well as the regeneration process.

The costs of programming a diesel particulate filter are, depending on the brand and type of machine.

Benefits:

- No more maintenance costs on the diesel particulate filter

- More torque at low rpm because there is no more back pressure

- Lower fuel consumption up to 10% !!

You can adjust the particulate filter for the following machines, among others;

- John deere R&M series with Phoenix L21 ECU (Tier 4A)

- John Deere R Series with L33 ECU is in test phase

- New Holland T5 with Bosch EDC17C49 ECU

- Doosan equipped with particulate filter / Dpf with EDC17CV41 ECU